chamber DIMENSIONS

1000 Х 2000 Х 800 ММ

800 х 1800 х 600 мм

INSTALLED POWER- 40 Kwt

THERE ARE TWO TYPES OF GLASS TEMPERING

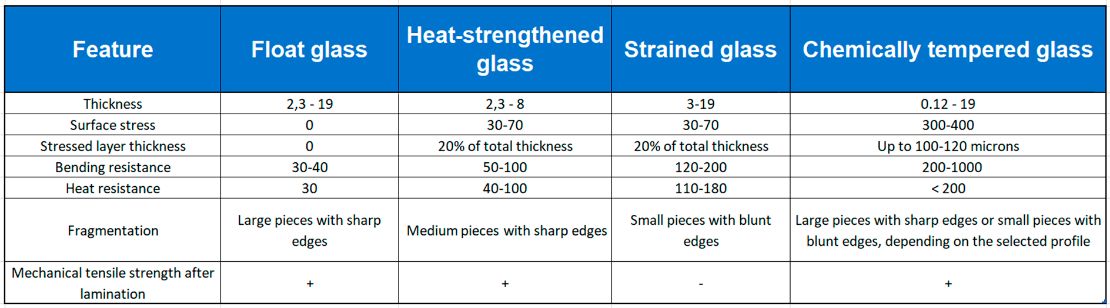

HOW GLASS PROPERTIES CHANGE AFTER TEMPERING?

WHERE IS TEMPERED GLASS USED NOW?

PRODUCT EXAMPLES

WE PRODUCE EQUIPMENT FOR CHEMICAL GLASS TEMPERING

THE EXPERIENCE WE SHARE WHEN YOU BUY EQUIPMENT

FAST CYCLES FOR ELECTRONICS

EXTRA STRONG GLASS - YOUR ANALOGUE OF GORILLA GLASS

SCRATCH-RESISTANT GLASS

FLOOR LIGHTS

ARMOR

THIN FRACTURED GLASS

and other developments.

OUR RANGE OF HFD X-TEMP FURNACES

OUR FURNACES WILL MAKE YOUR PRODUCTS UNIQUE!

AND THAT'S WHY:

FOLLOW US ON

IN SOCIAL NETWORKS

In order to get a consultation or buy a furnace for glass chemical tempering HFD X-TEMP call us at +7 (495) 968-71-35, write to zakaz@hfdhouse.ru or leave your contacts in the feedback form below!

© 2021 by Delobot. All rights reserved. We know how to create a cool selling website for you.